Extending building life

Extending the life of a structure enables more value to be extracted from the resources invested to build, operate and maintain it. Steel’s inherent flexibility makes it the material of choice for renovating and refurbishing buildings, for example:

- Long-span beams allow large column-free spaces, providing flexibility in the floor plan

- Major alterations are readily made – due to steel’s light weight, extra floors can often be added without overloading existing foundations.

Build faster with less disruption

Overall construction programmes are shorter using steel thanks to:

- Efficient and precision off-site manufacture and prefabrication

- ‘Just-in-time’ deliveries

- Steel’s superior strength-to-weight ratio

- Rapid installation by fewer people, in any weather

- Reduced disruption and disturbance around the site.

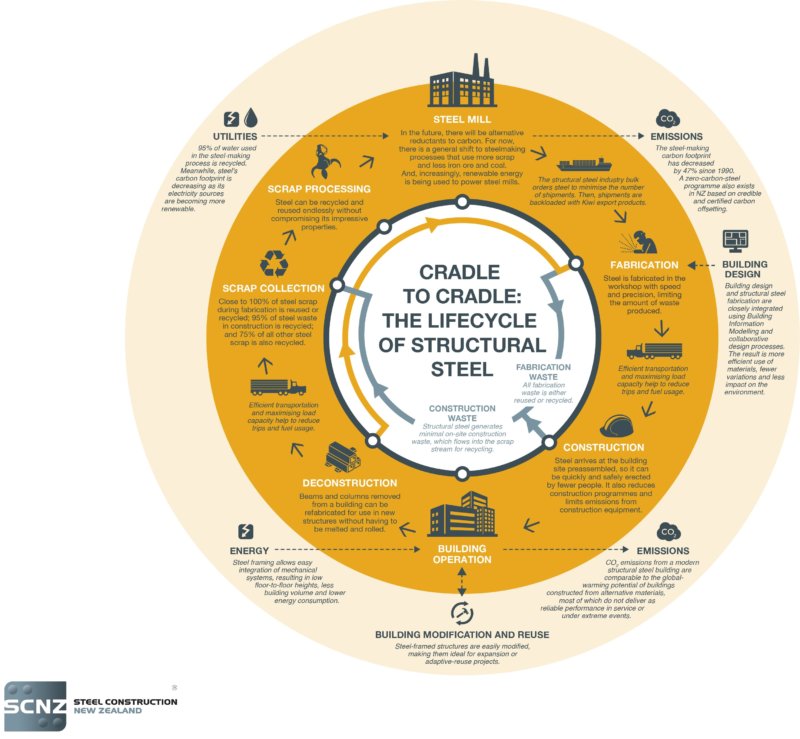

Minimal waste

Steel construction’s low-waste credentials benefit all stages of the construction lifecycle:

- By-products of the steel-making process can be usefully employed elsewhere. Slag, for example, is used as lightweight aggregate for roading

- Any waste generated during steel manufacture and fabrication is recovered and recycled in the steel-making process

- Automated, computer-controlled production lines turn out high-precision steel components, minimising defects and waste

- Steel can be easily recovered at the deconstruction phase and reused or recycled.

Competitive emissions profile

Carbon emissions are an important factor in measuring sustainable performance, and steel stacks up.

A Ministry of Agriculture and Forestry-commissioned report1 demonstrated that, on a whole-of-life basis, steel’s environmental performance compares favourably to other materials such as concrete and timber

Thermal mass acts as a heat sink, tempering a building’s internal environment by reducing and delaying the onset of peak temperatures. Put simply, it keeps the building cooler in summer and warmer in winter and reduces reliance on air-conditioning. Optimal thermal performance over a 24-hour period is achieved using only a 100mm-thick floor slab. All forms of steel-concrete composite construction meet this requirement.

For more information about steel’s sustainability credentials, visit the Sustainable Steel Council website.