FLOOR VIBRATION

In recent years there has been increased demand for office buildings that are fast to construct, have large uninterrupted floor spans and offer flexibility in their final use. This, along with the obvious benefits of lighter superstructures in a seismically active country, has made the dynamic performance of floors an important consideration in building design.

While there is a subjective element to perceptions of flooring vibration induced by human activity, there are now internationally recognised performance criteria included in standards.

Until recently a lack of robust methods for assessing the vibration performance of floors has made it difficult to accurately predict their dynamic performance. A new method – based on extensive European research that includes both in situ measurements of the vibration performance of a number of buildings and computer simulations – is now available.

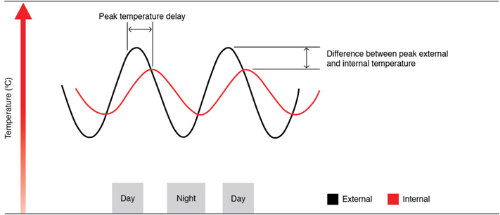

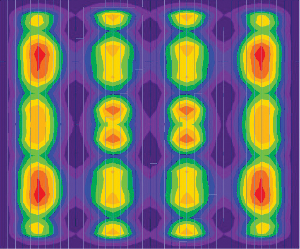

Design of Floor for Vibration: A New Approach, developed by the UK’s Steel Construction Institute (SCI), uses a finite element approach to determine the accelerations at various points on the floor due to walking activity. These accelerations are then compared with the limits cited in the international standard ISO 10137 to determine if the response of the entire floor is acceptable. Software is commercially available to implement this procedure; it produces contour plots of floor response to allow designers to easily identify areas of the floor with excessive vibration. Designers can easily modify the structure locally to reduce the floor vibration to acceptable limits.

This approach has been used in the UK since 2004, including some very exacting applications. Previously there was a perception that only very heavy floors could guarantee adequate vibration performance of suspended floors. In the UK this perception was limiting the use of structural steel-concrete floor solutions in vibration-sensitive areas such as hospital operating theatres and test laboratories. With the advent of a reliable design method, structural steel now enjoys a high market share in the health sector.

In New Zealand, SCNZ has assisted a number of consulting engineers to assess the vibration performance of local projects using the SCI’s methodology (the Finite Element Analysis package) and Oasys GSA Footfall analysis.